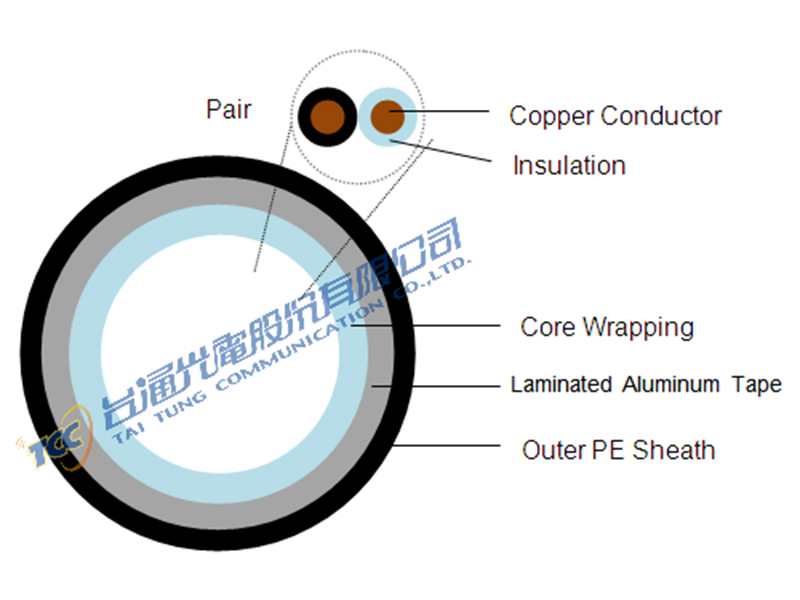

Polyethylene Unit Twin Cable with Moisture Barrier Sheath

CP-FS-HUT-LAP

This high quality insulated cable used subscribers distribution. Featuring: The cable is insulated full color coding with an extruded foam-skin insulating high-density polyethylene compound in the air space to water resistant filling compound.

‧ Conductor:Solid annealed copper wire size 0.4、0.5、0.63mm。

‧ Insulation:Foam-skin polyethylene

‧Twinning:Two insulated conductor are twisted into a pair.

‧Cable Formation:

Twisted pairs are assembled to form a substantially cylindrical group of 25 pairs (called unit).When desired for lay-up reasons; the units are divided into two or more sub-unit.

If the cable size up to 50 pairs and including 50pairs,Cable will consist of 10 pairs stranded together to form a compact bunch, which can be further divided into two sub-units of 5 pairs.

‧Unit identification tape

‧core wrapping

‧cable identification tape

‧Moisture barrier

‧Ripcord

‧Sheath:PE

Electrical Characteristics at 20℃

|

Item\Conductor Diameter |

0.4 |

0.5 |

0.63 |

||

|

Conductor Resistance (Ω/km) |

Maximum individual value for 99%of cases |

143 |

91 |

58 |

|

|

Max value |

150 |

96 |

60 |

||

|

Min. Insulation Resistance(MΩ/km) |

Min 6,500 500V d.c/1min. |

||||

|

Spark test of sheath |

KV |

6 |

|||

|

Mutual Capacitance |

Maximum Average Value |

53 |

53 |

56 |

|

|

Maximum individual value for 99% of cases |

60 |

60 |

60 |

||

|

Capacitance Unbalance (at 1kHz) |

Max. individual value for adjacent pairs(Pf/500m) |

275 |

|||

|

Far-End Crosstalk Loss (at 150kHz) |

RMS |

Min.67.8 dB/km |

|||

|

Any pair combination |

Min.57.8 dB/km |

||||

|

Near-End Crosstalk Loss (at 772kHz) |

Unit Pair Size |

M-S dB |

|||

|

Within Unit |

13 or less |

Min.56 |

|||

|

25 |

Min.60 |

||||

|

Between Unit |

Adjacent 13 or less |

Min.65 |

|||

|

Adjacent 25 |

Min.66 |

||||

|

Non-Adjacent |

Min.81 |

||||

|

Attenuation Nominal (dB/km) |

40 kHz |

8.5 |

5.9 |

4.1 |

|

|

120 kHz |

11.3 |

7.7 |

5.5 |

||

|

150 kHz |

11.8 |

7.9 |

5.9 |

||

|

772 kHz |

21.3 |

18.4 |

13.1 |

||

|

Dielectric Strength |

Conductor / Conductor |

A.C.360/2(R.M.S); D.C.550/1 |

|||

|

Conductor / Ground |

A.C. 1000/2(R.M.S); D.C.1500/1 |

||||